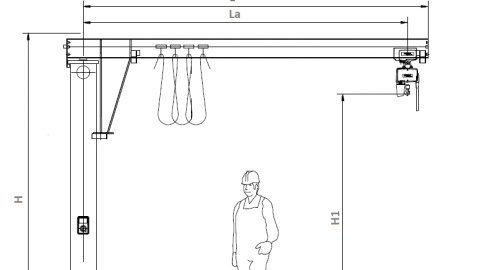

A cantilever jib crane is an excellentchoice to accelerate work withinproduction lines, workstations,workshopsor warehouses. Thesecranesfeaturefastinstallation andeasy maintenance. Cantilever jib cranes can be either manually operated or motorized and perform a multitude of functions within a work area. The maximumjib(bracket) length can be up to7 m.Cantilever jib cranes are available in capacities up to 5 t.Cranes canbeused forindoorandoutdoor service atroom / ambienttemperaturesrangingfrom -20°C to+40°C.

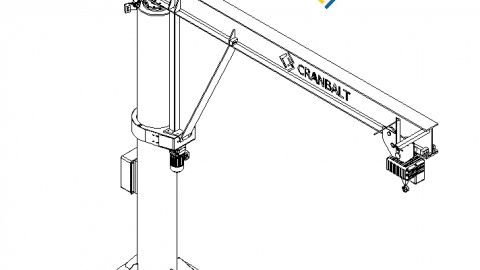

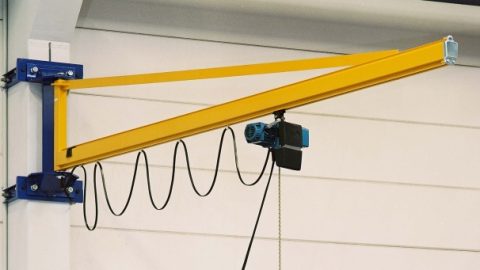

Cranbalt offers two types of cantilever jib cranes: with a pipe mast (floor or foundation mounted) and without a pipe mast (wall or column mounted).

Cantilever mast jibcranes are designed to be used bothindoorsandoutdoors.Jibcranesthat do not have a mastareused on fully equipped premises which lackspace for a floor mounted cantilever mast jibcrane.

Cantilever jib cranes guarantee minimum dimensions and maximum use of space.