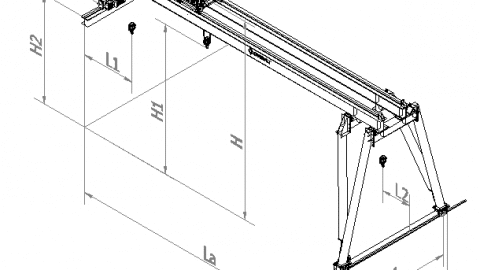

Gantry cranes are mounted on rails installed on the ground whereas semi-gantry cranes have one side of rails mounted on the elevated runway. The maximum load capacity of these cranes can reach up to 100 t, the maximum span up to 40 m, and the lifting height up to 15 m. Based on the type of design, gantry cranes can be single girder or double girder, with or without brackets.

Depending on the load type, container cranes can be used. Cranes are supplied with a hook, grapple attachment, magnet or vacuum beams. These cranes are used for loading / unloading, storage and other applications in open warehouses, railway stations and ports.

Cranes can be used for indoor and outdoor service at room / ambient temperatures ranging from -20°C to +40°C.

Gantry cranes can be operated from the ground via cable-connected control pendant, radio remote control or from an operator’s cabin. In addition, multiple controls are possible by switching control from one mode to another. The system allows operation of the crane in a manual, semi-automated or fully automated mode.

Cranes can be supplied with one or two loading trolleys based on the number of trolleys used. A trolley can feature a primary or assistance lift function. An option of long open floor spaces, stability, a wide span and high speed represent the major advantages of this type of cranes.

The crane can be provided with custom service platforms, maintenance walkways and auxiliary lifting equipment. The crane itself can be manufactured with explosion-proof installations.