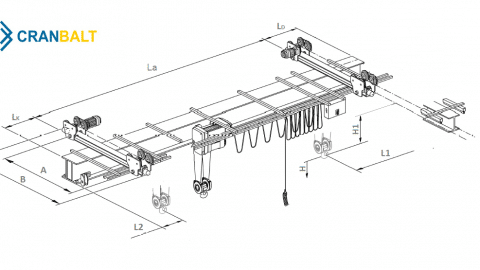

Underhung cranes are employed where the build allows the installation of crane runways. The capacity of the suspension crane must be selected considering the impact of the crane load and the runway load on the build. The maximum load capacity of these cranes can reach up to 10 t, the maximum span up to 24 m. Based on the amount of runway beams there are single-span and double-span suspension cranes. Ambient temperatures can range from -20°C to +40°C.

Underhung cranes are operated from the ground via cable-connected control pendant or radio remote control. In addition, double control is possible by switching control from control pendant to radio remote control, and vice versa. Cranes can be equipped with one or two hoists based on the number of hoists used.

Underhung cranes are cost-efficient and lightweight. Their compact and lightweight design requires less building space and ensures efficient use of the building height.

These cranes are supplied with a hook, magnet or vacuum beams.